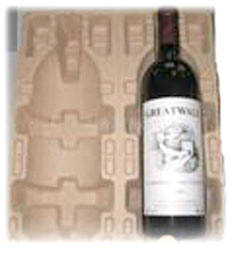

Products - Molded Pulp

Molded pulp is a sustainable packaging material,

Typically made from recycled paperboard & newsprint , can be recycled again after is useful life cycle .

It is used for protective packaging , food service trays and beverage carriers.

The process involve vacuum forming and transfer molds, where the mold is an extremely fine wire mesh in the shape of the upper/exposed surface. The fibrous slurries are frequently made up of a high percentage or entirely of recycled paperboard & newspaper, which produces a relatively smooth surface on one side and a fairly smooth surface on the opposite side with good accuracy and definition

Process flow :

- Pulping

- Forming

- Nature or hot air oven drying

- Hot press -- with or without emboss

- Trimming -- depend on product application

- Packaging

- Delivery

.

Why pulp mold ?

- 100 % post consumer waste with biodegradable properties , Non toxic & No waste & pollution

- Cost effective – less expansive compare to expanded polystyrene ( EPS) , vacuumed formed ( PET)

and PVC , corrugation and foams - Space saving design – smaller in size resulting lower shipping cost & warehousing cost , 100% retrievable

- Conforms to ISO 9001 & ISO 14001 standard

- Good resistant to shock , crushing resistant and buffer capacity

- Water resistant & temperature resistant

- Go GREEN and promote company image , less taxation for EU market & no CFC damage to ozone

Pulp production machinery

1x pulper

2 x forming machine

1x thermo oil drying system

4 x 20 mt hot press machine

2 x 20 hp trimmer

Present capacity : 10,000 pcs daily